In this blog post, Reece, one of our lab technicians explains more about Advanced Data Recovery

We have plenty of cases which commonly tend to surprise us with their peculiarities and differences varying between one another and this is especially true with hard disk drives which move onto our Advanced Data Recovery stage.

So What is Advanced Data Recovery?

Advanced Data Recovery (ADR) is our process which we deem specific drives fit for dependant on a variety of key factors usually relating to physical damage to the internals of the device, this skilled process goes beyond the traditional more common methods of data recovery in order to extract important, crucial data from a damaged patient device.

What Do We Do?

The Advanced Data Recovery stage is a process which Data Clinic have spent years mastering the techniques behind, this is something only few places are capable of and I’d like to confidently say that we are likely the best around. The process usually entails this:

The customer will have a drive which has sustained physical damage which can be due to a plethora of reasons: dropping, knocking, spillage, electronic power surge and so forth.

The drive will be internally inspected to determine whether it is viable for our cleaning processes and physical mechanical work to ensue.

Necessary information such as number of platters, parts requirements, logical information from within the ROM of the drive such as Pre-Amplifier info will be gathered.

This will then be discussed with the customer to ensure they have all the information they require in order to make a decision themselves on whether they wish to go ahead or not.

Below is an example of a recent case which required our ADR service, the process and what we did to recover the data will be explained:

Case arrived with us and drive details were noted so that we can gather more of a thorough idea regarding the device which we will be handling and dealing with:

Drive: ST8000AS0002

Notes: This drive is a newer 8TB Seagate model which holds 6 platters containing data written across all 12 surfaces.

The drive was connected via SATA then powered to listen for any peculiar noises, what was immediately noticed was a distinct clicking but also grinding sound from within. Drive was almost instantly powered down to prevent any further internal damage from occurring and prepped for clean room inspection.

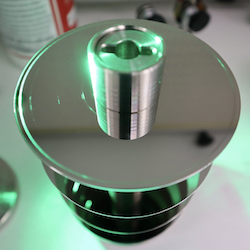

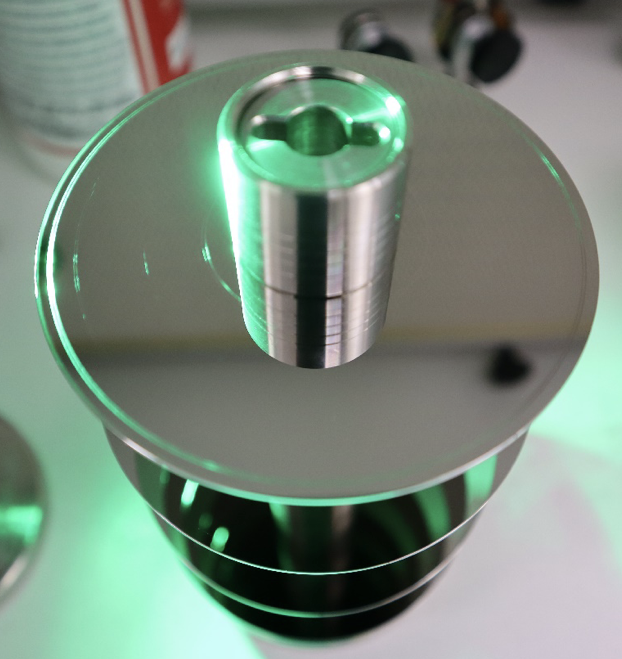

Upon removal of the lid and seal from the drive I noticed right away that the heads had caused physical damage to the platter surfaces leaving residue and what looked to be faint scratching marks simply from where the heads have unfortunately been hitting the platters, drive was recommended our ADR Diagnosis Stage 1 process which involves removal of the heads and platters themselves to allow us closer inspection under green light and a microscope to gather a much more detailed and in depth idea of any further damage which this drive might have sustained plus if it is viable for Stage 2 ADR being our extensive repair, cleaning process and basically an overhaul of the drive’s internals.

The customer wanted to proceed with this and so the necessary work was carried out like so:

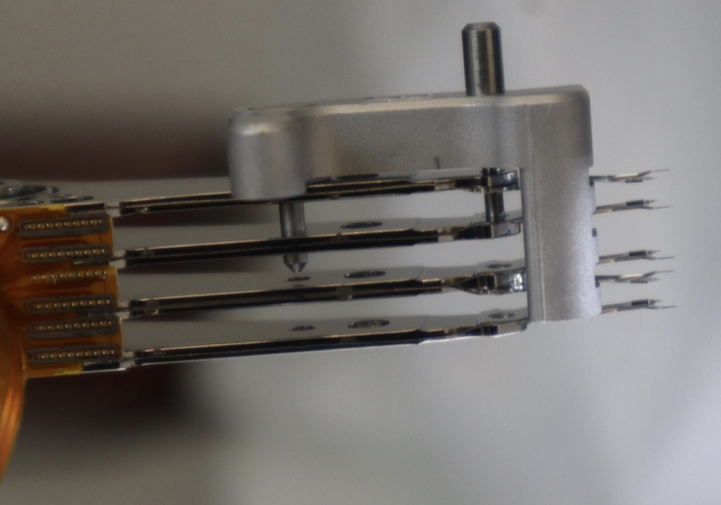

The heads are removed first to allow inspection under a microscope to check for any specific markings/cracks/lubricant/missing heads which might indicate head crashes further into the drive or perhaps the lubricant layer breaking away from the platter surfaces.

This is key information to us as it allows us to uncover whether a surface within the drive looks fine to the naked eye but perhaps has further damage lingering which could potentially ruin new parts if they were to be introduced, the parking ramp for the heads is also thoroughly inspected to ensure there are no cracks or bits of debris on it as these are all small imperfections which can lead to monumental damage further down the line.

Once all of this is complete, the process of platter extraction takes place which includes a variety of steps such as marking the platters in a way to ensure we do not lose the original cylindrical alignment of where the platters are situated as this causes the heads to lose the location of which they expect data to be which in return causes mass corruption and unreadable data as a whole. For example, head 0 correlates to surface 0 which has a specific zone that the head is expecting to reach and if this zone is skewed then this is a serious problem for data retrieval.

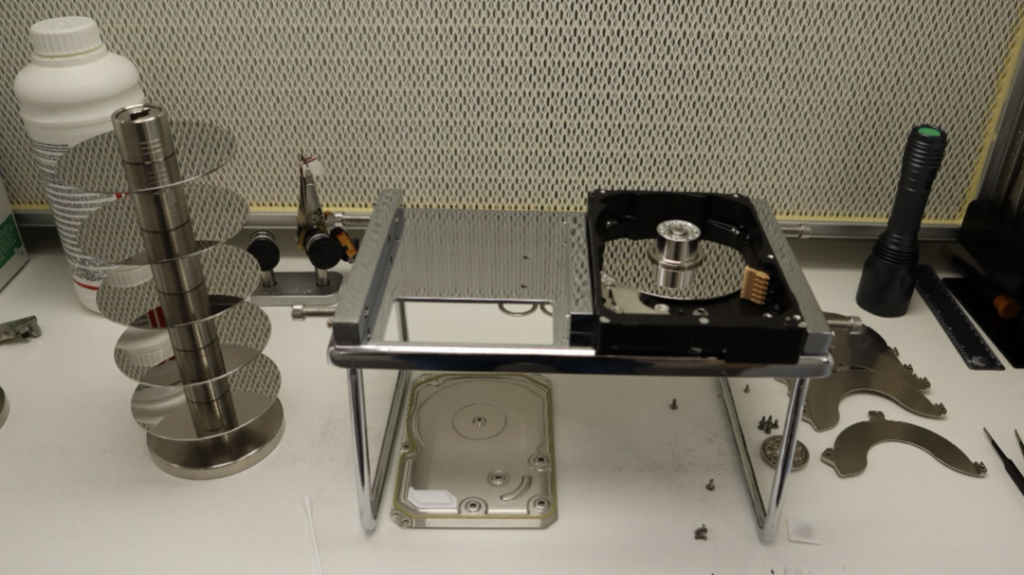

Screws are carefully removed from spindle and cover is then carefully loosened/removed which allows me to begin extracting the actual platters, this process has to be planned step by step and I have to remember exactly what I have done in order to replicate and reverse the process again. Platters are removed using a precise suction tool and then placed onto a platter stand which allows close inspection whilst keeping them a safe distance from one another, below is what the drive looks like after being stripped down:

To no-one’s surprise this drive had sustained further damage to various of it’s platter surfaces and thus required extensive cleaning and physical removal of multiple heads in order to attempt to get the very best recovery, the reason head removal is necessary sometimes is because a head crash for example causes an indentation in the surface which if the delicate heads were to hit can completely destroy them. This same issue prevails with degradation of the lubricant layer on a platter surface typically the case when a head crash has occurred, the chemical used for cleaning will begin to pool and leave residue and overall feel incorrect upon application. Below is an example of what a platter surface with a head crash may look like and what a stack of heads with head 3 cut off looks like (the heads are not specific to the case at hand:)

Once all of the components are carefully reintroduced back into the chassis and drive powers all okay, there are logical parameters set which then take place via firmware modification within the PC3000 utility to switch off the necessary heads within ROM code which allowed me to produce the absolute best clone of the customer’s damaged Hard Disk Drive and prevent the drive from attempting to read on these non-existent heads and overcome any obstacles which may arise during this.